Our services span the entire project lifecycle, including feasibility studies, detailed project reporting, basic and detailed engineering, procurement support, erection, testing, commissioning, and post-commissioning assistance. We work closely with clients to ensure customized solutions that meet their technical, operational, and budgetary requirements.

With a commitment to quality, safety, and innovation, ShaktiPunj Engineers continues to set benchmarks in timely delivery and cost-effective execution. Our strong track record of successfully commissioned projects and repeat orders reflects our client-first approach and dedication to engineering excellence.

Power Generation from Waste Heat Liberated from Rotary Kiln

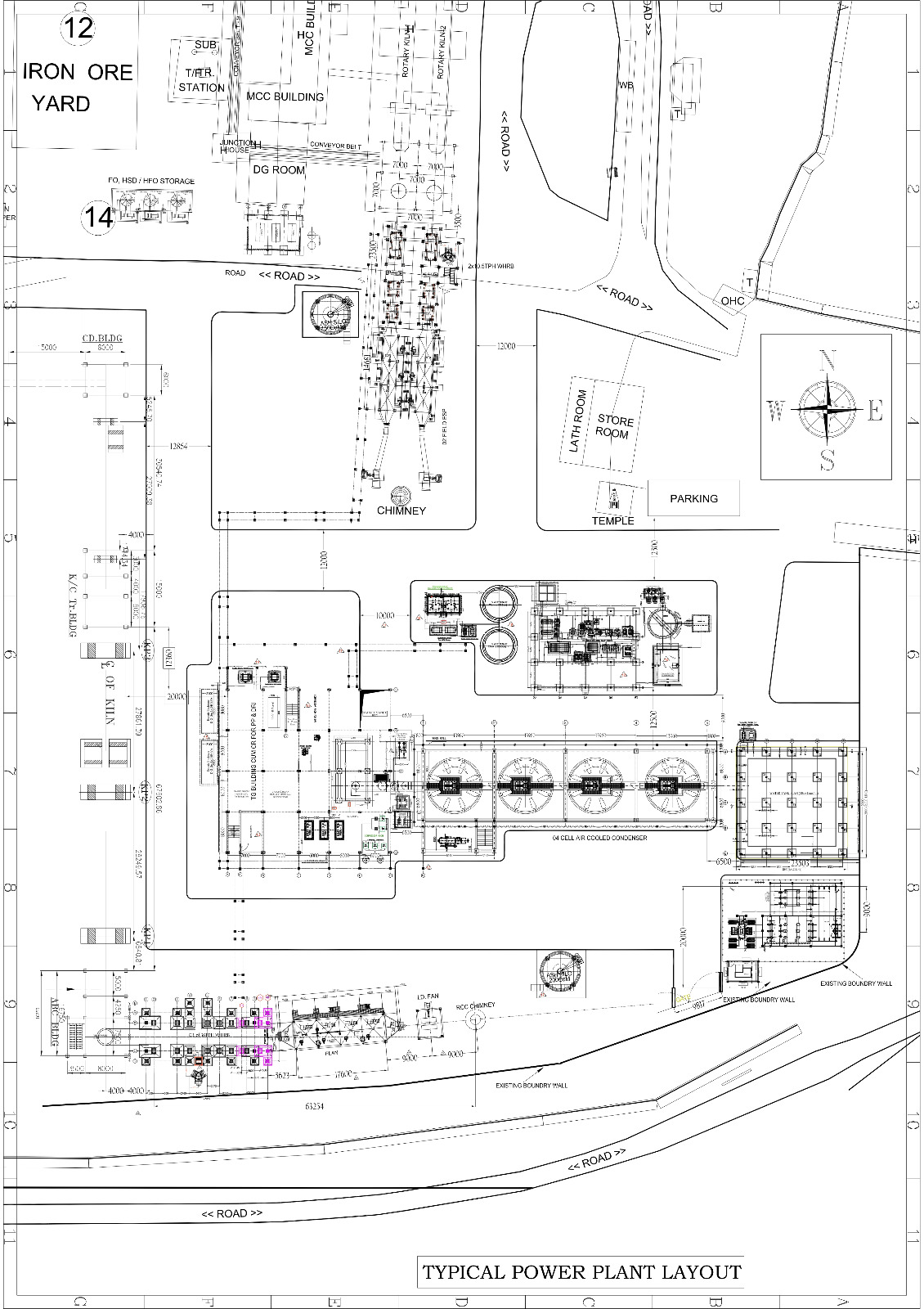

At ShaktiPunj Engineers, we specialize in designing and implementing Waste Heat Recovery Systems (WHRS) for coal-based DRI (Direct Reduced Iron) plants. In these plants, only about 35% of the heat generated from coal combustion and reduction is used directly in the reduction process—the remaining 65% is wasted as flue gases. This significant energy loss presents a major opportunity for energy recovery and in-house power generation.

Our Solution

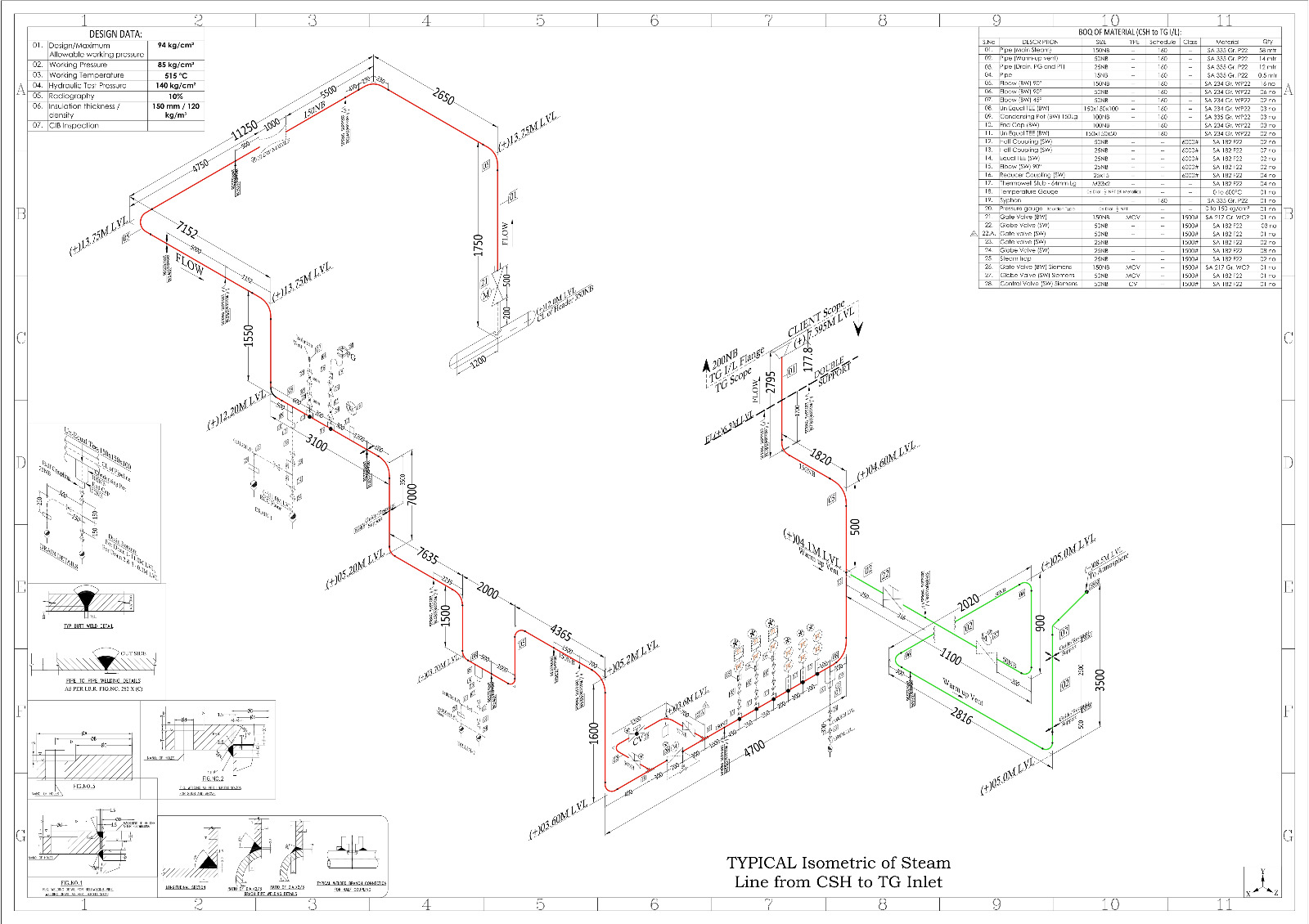

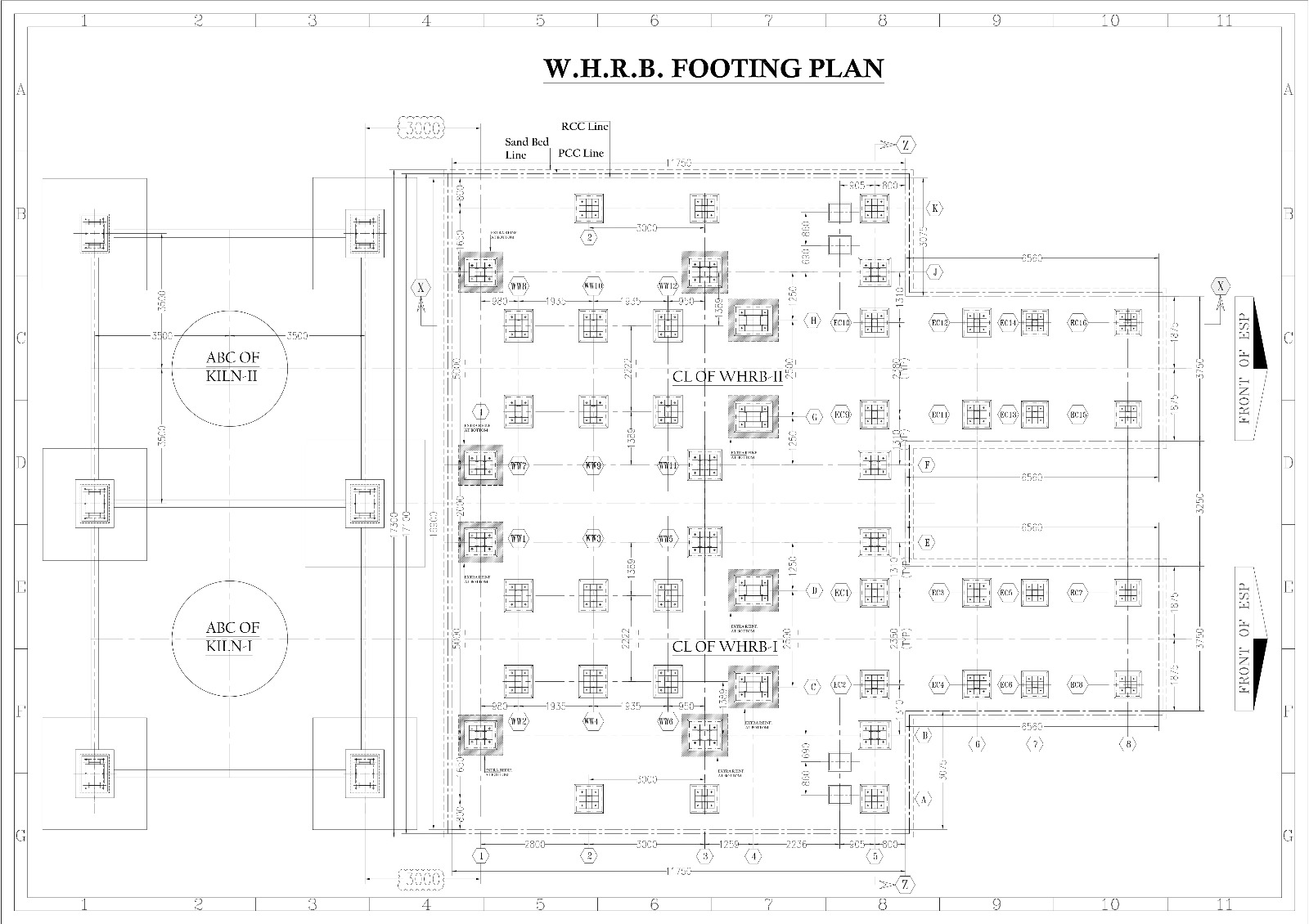

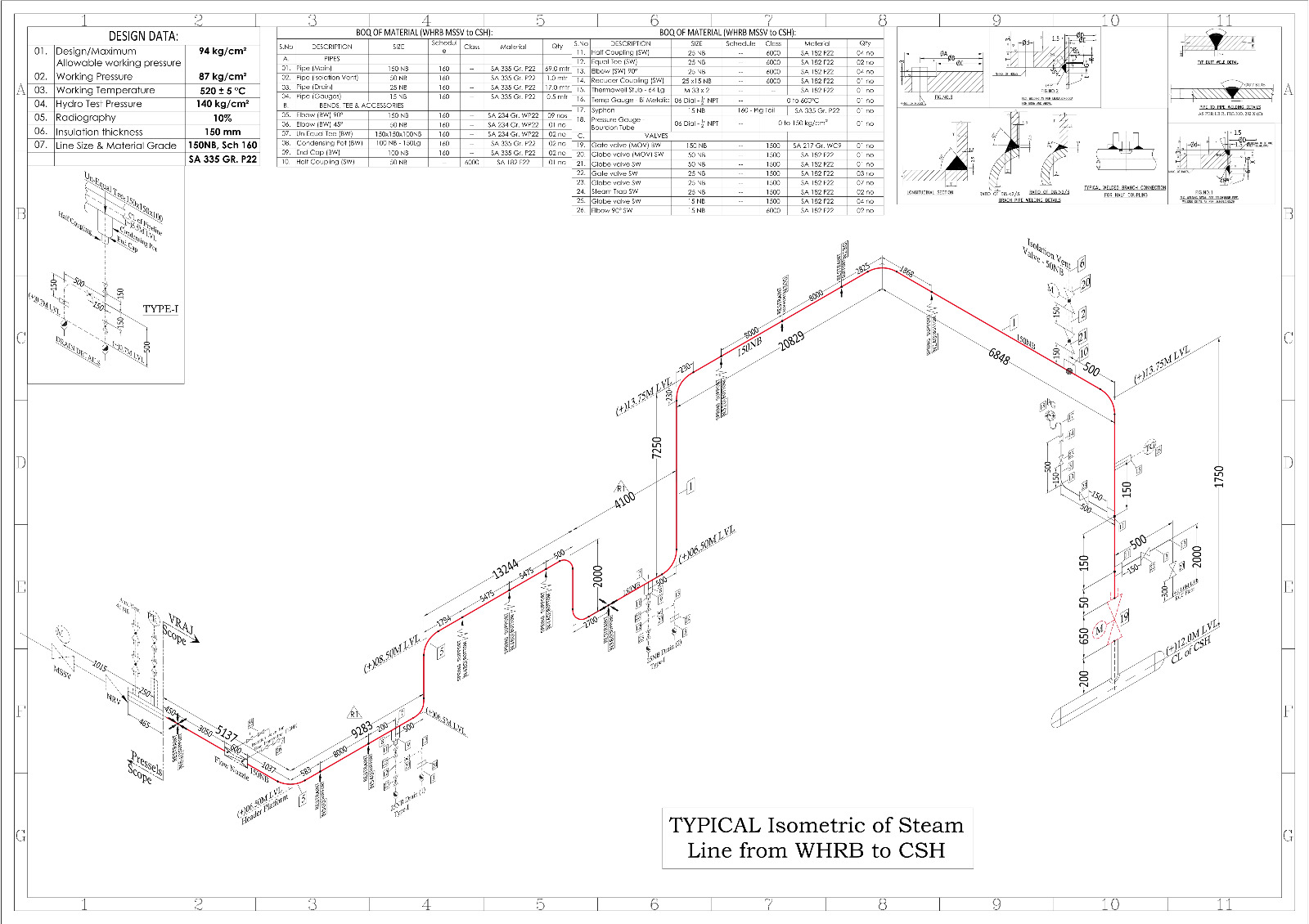

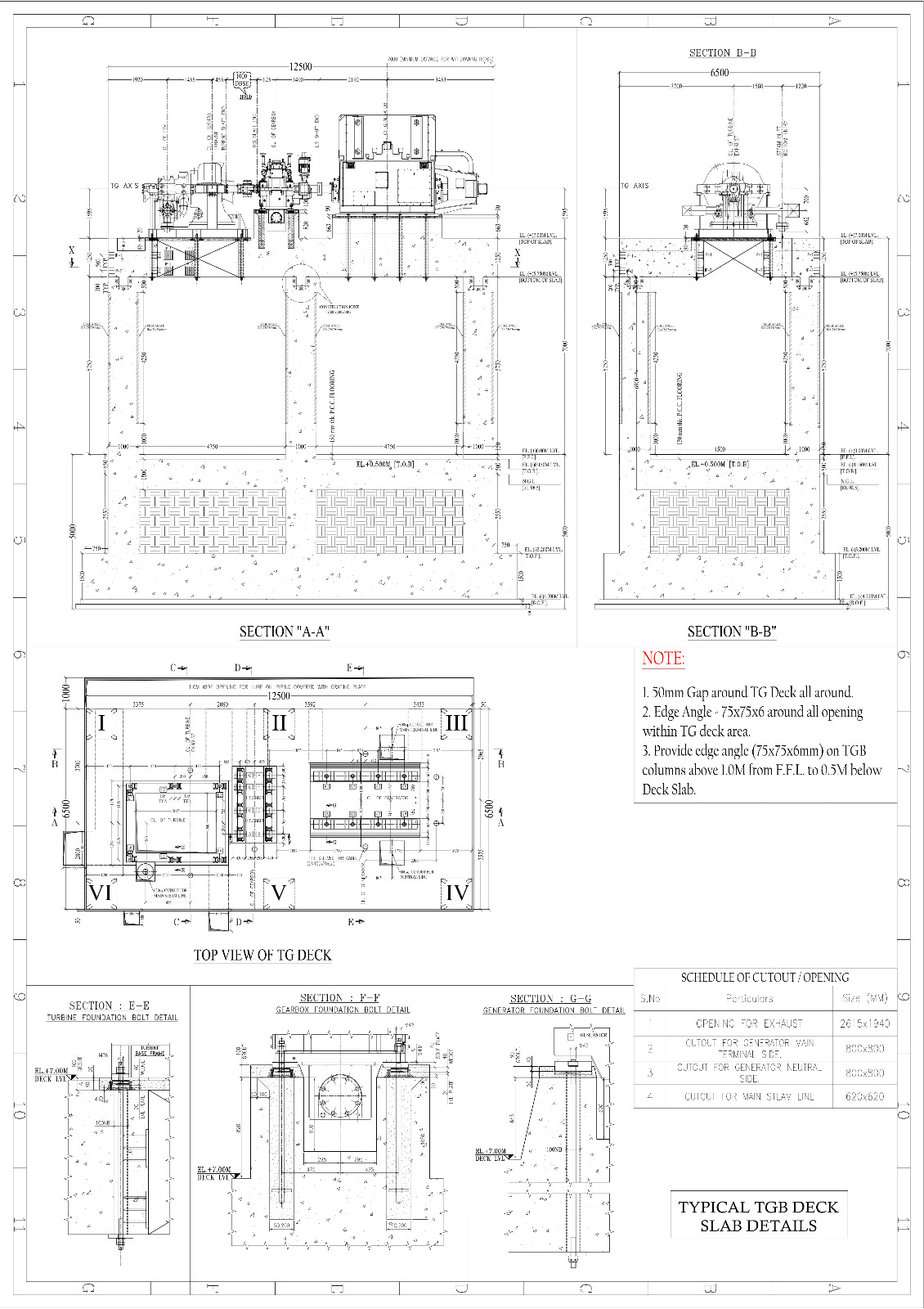

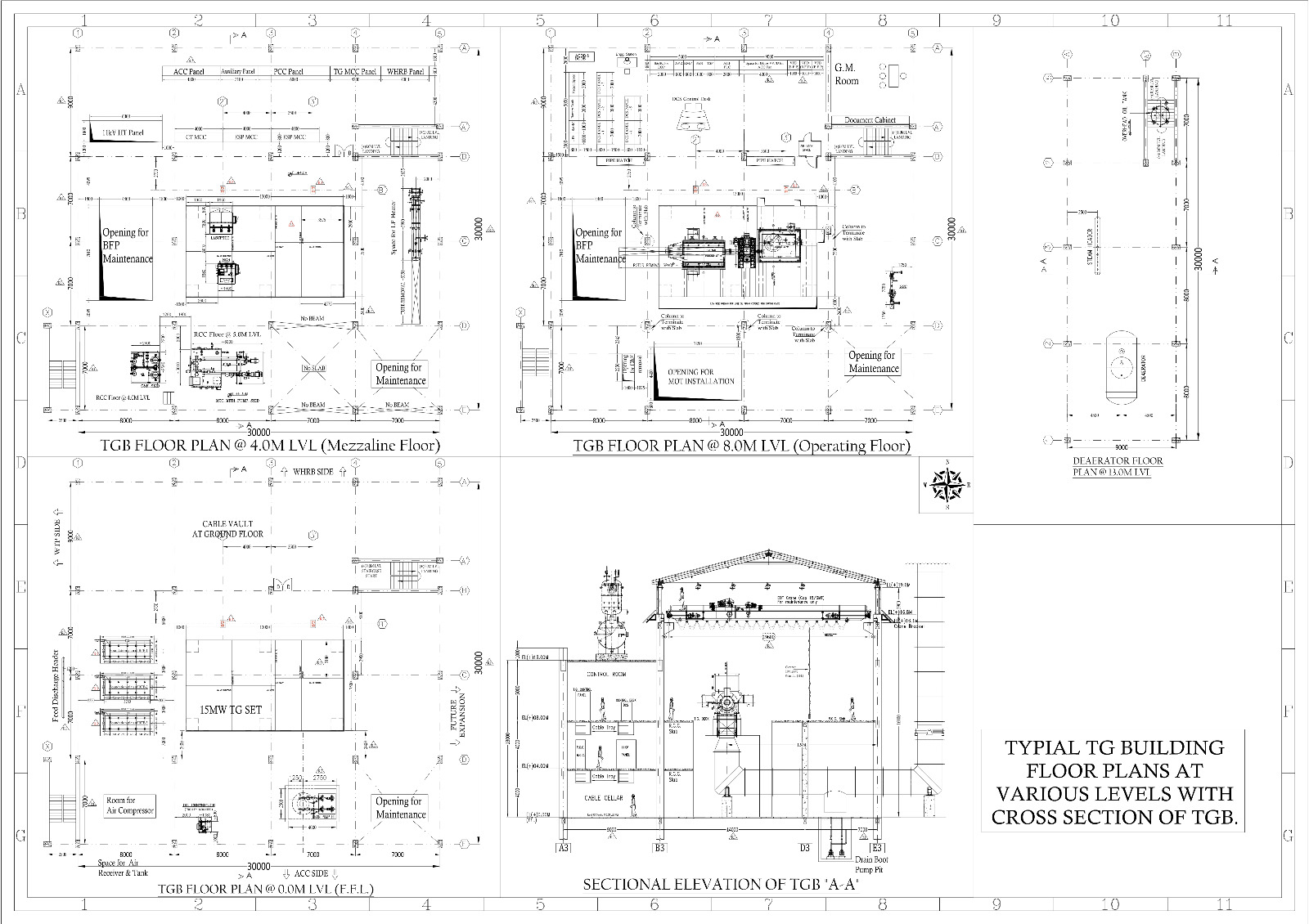

We harness the untapped energy from high-temperature waste gases emitted by the Rotary Kiln (typically at ~1000°C) through an integrated Waste Heat Recovery Boiler (WHRB) system. This unit captures the sensible heat and converts it into high-pressure, high-temperature steam, which is then routed to a Steam Turbine Generator (STG) to produce electric power.

Benefits of Our System

Self-Sustained Power Supply: The generated electricity can meet the complete power demands of the DRI plant—including raw material preparation, utilities, administrative offices, and even staff housing colonies.

Export Possibility: Surplus power can be exported to the grid, generating additional revenue.

Efficient Energy Utilization: Heat recovery reduces dependence on external power sources and lowers operational costs.

Environmentally Friendly: Reducing waste heat emissions improves the plant’s carbon footprint and aligns with sustainability goals.

System Design Considerations

The efficiency of heat recovery and power generation depends on key parameters:

Gas Temperature

Mass Flow Rate

Continuous Availability of Gases

By optimizing these factors, our engineers ensure that your plant achieves maximum energy recovery with minimum energy wastage.